Air Bearing

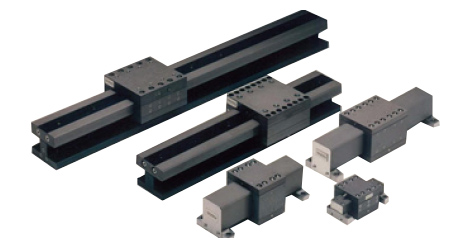

Example of stage structure

TOTO can propose optimal air bearing slides with high straightness and high repeatability using our air pad design and analysis technique.

TOTO's air slides are adopted in manufacturing and inspection systems for high precision parts in the semiconductor and flat-panel industries.

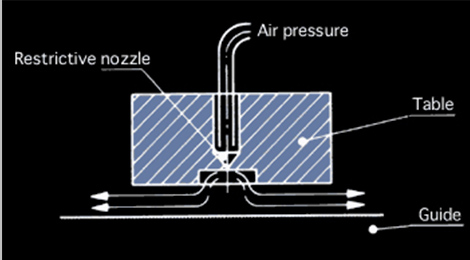

The Air Bearing Principle

An air bearing, a component of the air slide, is non-contact type bearing where the air pressure flows (0.4 MPa) against the guide through a restrictive nozzle to uplift and control precision movement. (See the picture.)

Chracteristics of Air Bearing

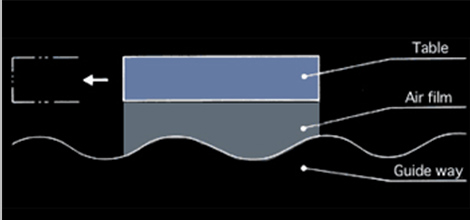

*Balancing effect

The table travels on a film of air and is not influenced by minute undulations on the surface of the guide way or table. Thus the floating effect is evenly sustained against to the table, and a precise position is available.

- ■ High repeatability.

- ■ Free from stick slip due to no contact.

- ■ Minimal vibration during slide motion.

- ■ As slide friction is minimal, precise positioning is possible.

- ■ Air slide principles use a balancing effect that provides accurate linear motion.

- ■ High speed can be attained without generation of heat from friction.

- ■ As oil or grease are not required. It is clean and maintenance free.

Application

- ■ Stepper

- ■ Inspection System for IC&LCD

- ■ High Precision Profiler

- ■ Ultra-precision machining equipment - Typical applications

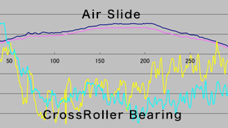

Accuraracy of Air bearing slide

TOTO's air bearings are known for exacting straightness and high rigidity.

We have a broad product semi. TOTO's air bearing systems are ideal for inspection equipment and process equipment applications, which require constant movement speed and precision placement.

Air Bearing

Air Bearing

-

Product Introduction

Comparison with other methods