Bonding Capillaries

Incorporating TOTO's own high-durability ceramic materials and combining high-precision and high-uniformity fabrication techniques, our bonding capillary contributes to improved productivity in the semiconductor assembly process. In addition, our advanced design and analysis capabilities and our expert engineering support contribute to the rapid resolution of customers' technical issues.

Long-life Ceramic Material PX™

Effect

① Long capillary life means less frequent capillary replacements with higher equipment utilization rates and lower costs.

② Long life capillaries keep their initial wire-bond pull-strengths and process window settings for longer periods of time.

This provides more lasting bond stability and improved assembly yields.

Material Characteristics

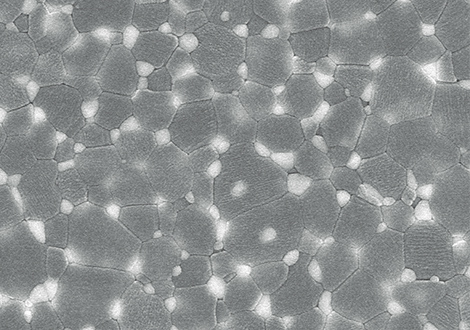

Improved capillary wear resistance is achieved by optimizing the ceramic’s physical properties and manufacturing processes.

TOTO's PX™ Material

| TOTO's PX™ Material | CompanyA | CompanyB | |

|---|---|---|---|

| Flexural strength | 1339 | 965 | 1195 |

| Micro-pore count [PPM] | 12 | 392 | 131 |

| Vicker's hardness. | 2032 | 1812 | 1953 |

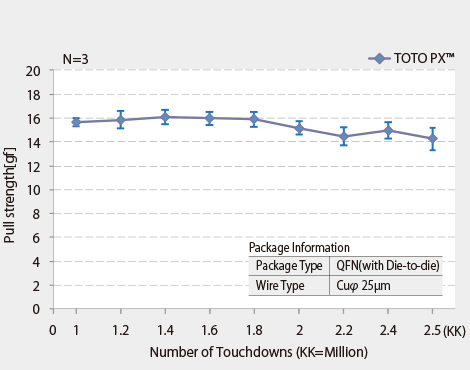

Long-life PX™ Material Test Result

TOTO's PX™ capillaries achieved 2.5 million bonds under challenging die-to-die condition and 3 million bonds with Roughened PPF Leadframe.

It's a remarkable improvement in tool life and cost per number of capillary touchdowns.

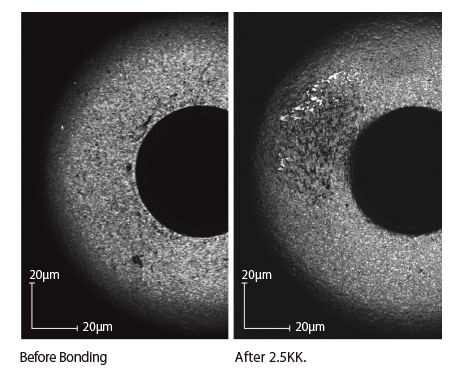

TOTO PX™ wire pull test result with die-to-die wires

No significant wear was observed at the capillary tip after 2.5 million bonds, proving PX™ material’s high wear-out resistance.

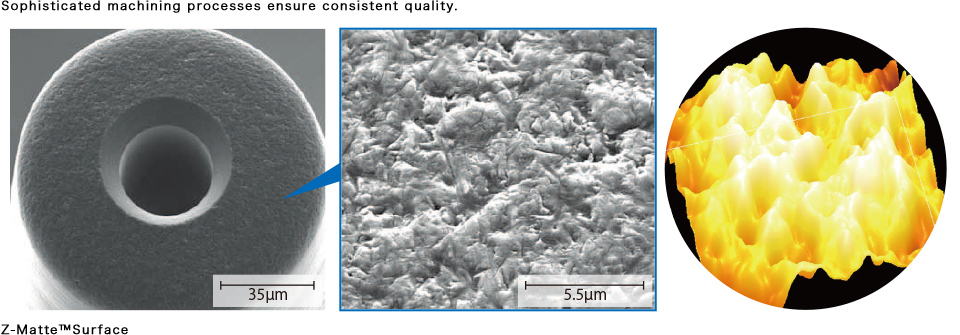

Rough Matte Tip Finish Z-Matte™

Z-Matte™ capillary tip surface finish uses rounded, durable peaks to provide the roughest matte surface finish in the industry(*).

Lower wire-bonder parameter settings can be applied so that tip wear-out is reduced and same 2nd bond performance can be achieved on tough lead frame material such as Ni/Pd/Au PPF lead frames. Capillary surface roughness and tip shape can be preserved by reducing the stress loadings which normally focus onto small areas of the capillary tip.

*By own investigation in November 2014.

*The arithmetic average roughness Ra is the index of roughness.

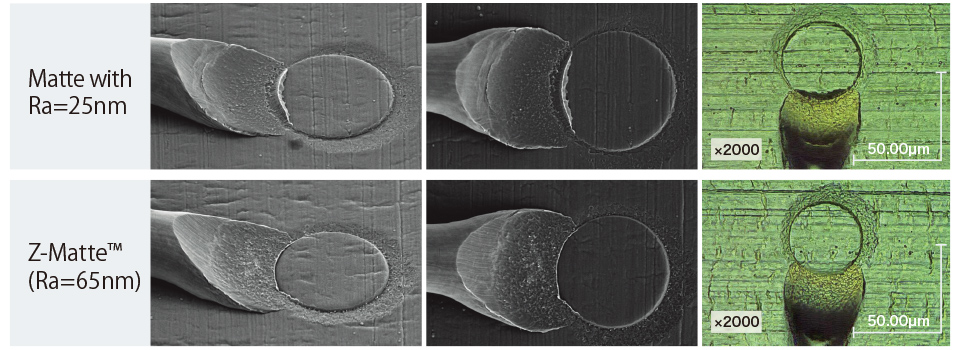

Z-Matte™ Surface

Z-Matte™ surface finishes ensure good 2nd bond performance even under difficult bonding conditions.

Visual analysis confirms more distinct capillary tip imprint features on TOTO's 2nd Bond-stitch crescents, demonstrating Z-Matte™ 's superior gripping force.

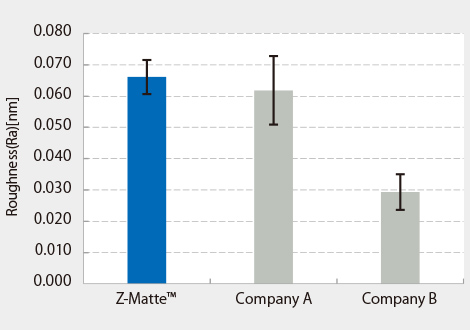

Capillary tip surface roughness comparison

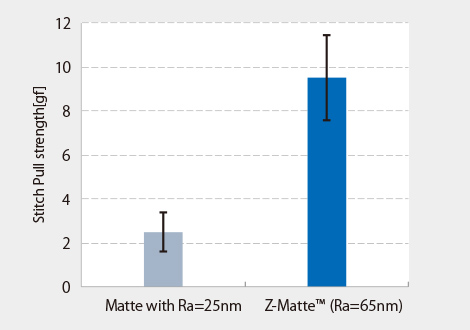

Stitch Pull Test (Package: Pd-PPF Cu-1.0mil)

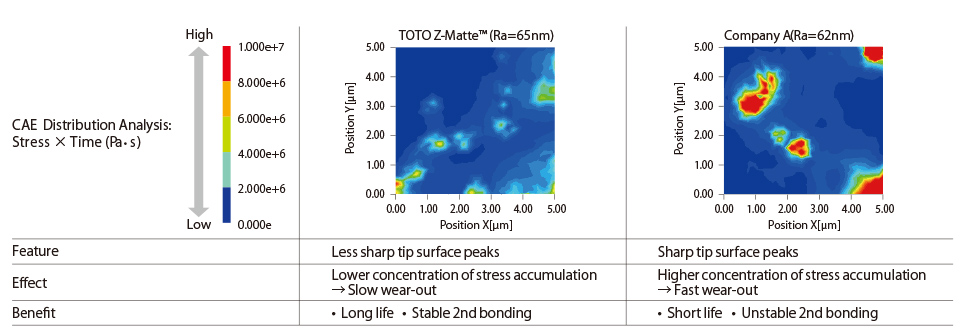

Impulse evaluation by CAE

By reducing the sharpness of the peaks on the capillary tip’s matte surface finish, stress induced, surface deformation can be minimized.

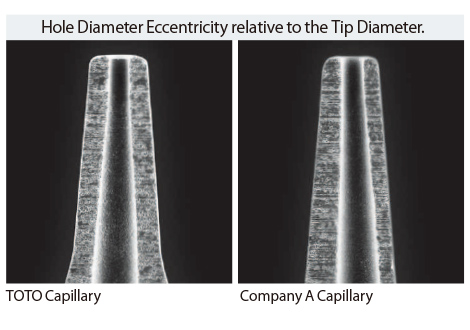

High Precision Processing Technology

TOTO's Bonding Capillaries are manufactured using state-of-the-art micro-machining equipment to ensure dimensional accuracy and repeatability. This precision process provides stable bonding and consistent capillary performance, under the most severe wire-bonding conditions.

Technological Advantage

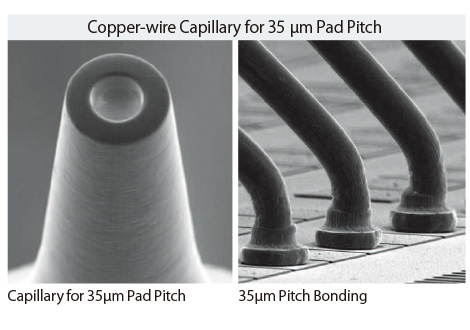

①Precision Wire-bonding :

Thin bonding wires and narrow pad pitches are common challenges in high density and mixedtechnology IC packages.

TOTO offers precision Bond Capillary tools capable of bonding 15 μm wire diameters on bond pad pitches as small as 35 μm.

②Bonding Uniformity :

Highly consistent wire-bonding accuracy is ensured with TOTO's micro-machining process technology,

which contributes to uniform bond-ability and improved MTBAs.

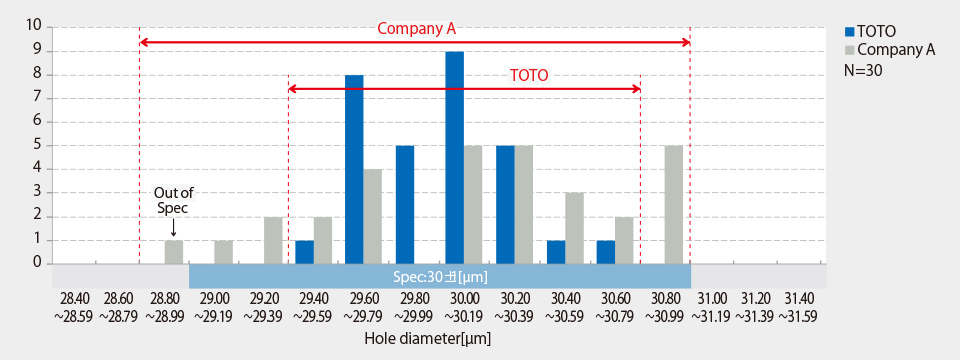

TOTO tightly controls capillary dimensions

Comparison of Hole dimensional control with same spec of 30±1[um]ɿTOTO vs Company A