Climate Change Strategies

Our Approach

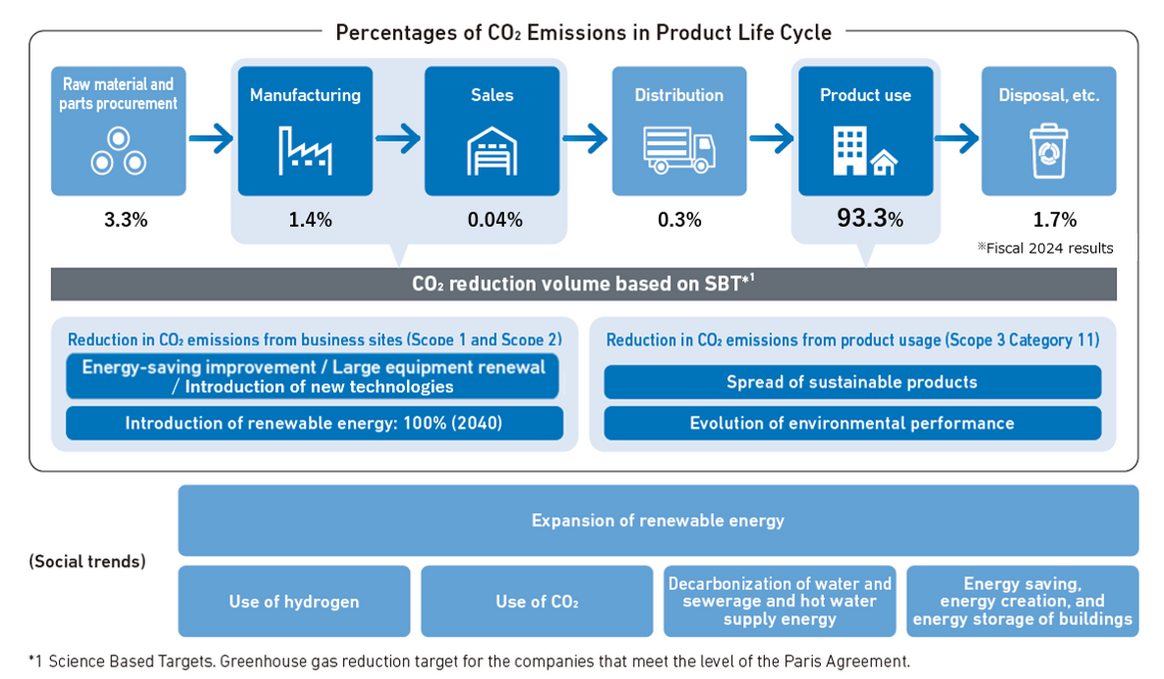

The TOTO Group recognizes the impact of climate change as a business risk, and works to reduce the emission of greenhouse gas based on the scientific grounds that are consistent with the Paris Agreement toward the realization of a carbon-neutral and sustainable society. On average, our products are used over a 20-year period, and if we look at this from the perspective of the entire life cycle this means the period of product use accounts for over 90% of our overall CO2 emissions. By actively working to reduce emissions in this stage of the life cycle, we aim to realize both comfortable and eco-friendly everyday lifestyles.

In regard to CO2 emissions from our business activities, we are promoting CO2 reduction plans that take into account analyses of climate change by 2050 and our long-term business growth by 2030. Under these plans, we are actively introducing renewable energy sources on a Groupwide basis.

Initiatives at Our Facilities

Results in FY 2024

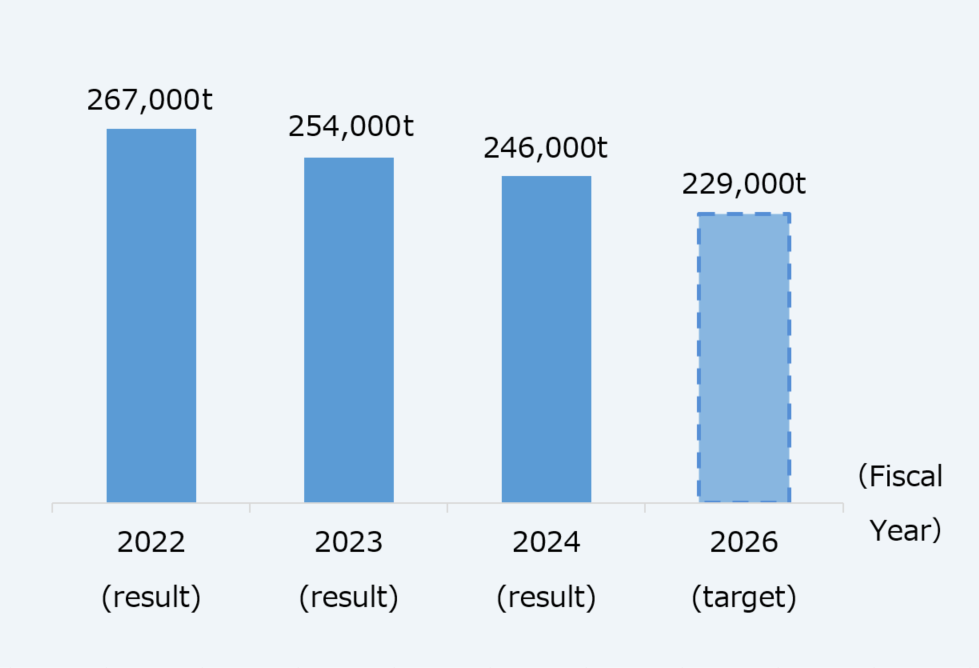

CO2 emissions from business sites in FY2024 were 246,000 tons.

In fiscal 2024, we will continue to improve productivity, promote Energy-saving measures, and expand the use of renewable energy at our global locations, and as a result, CO2 emissions from Business site were reduced by 8,000 tons compared to fiscal 2023.

Toward the realization of a carbon-neutral and sustainable society in 2050, we will promote CO2 reduction through the introduction of renewable energy and other measures that exceed the increase in CO2 emissions due to business expansion, aiming to reduce CO2 emissions to 229,000 tons or less in FY2026.

Total CO2 emissions from business sites

*CO2 emission coefficient

Electricity:CO2 emission coefficients from electricity purchased based on TOTO Group contracts.

Factor other than electricity: Guideline for Calculation of Greenhouse Gas Emissions (Version 5.0) published by Ministry of Environment and the Ministry of Economy, Trade and Industry of Japan

Initiatives to Curb CO2 Emissions

・Conversion to energy sources with lower CO2 emissions

We are promoting the shift to fuels and electricity that emit less CO2 in our business activities.Melting facilities in NANJING TOTO Co., Ltd., used in a casting process of enameled products, such as bathtubs and washbowls, were changed from cupola furnaces to electric ones in 2018, which had contributed significantly to improvement in energy efficiency and reduction in CO2 emissions in production by the conversion of energy for the equipment from coke to electricity. This re-equipping is also expected to prevent air pollution in the surrounding area of the factory.

We are also working on electrification of air conditioning systems and cafeteria kitchens in newly constructed plants.

In March 2025, we installed a hydrogen generator that electrolyzes water to produce hydrogen.By using electricity derived from renewable energy sources for electrolysis, the hydrogen produced is green hydrogen.We aim to establish a new firing technology that produces less CO2 emissions by co-firing the green hydrogen produced in the firing of Sanitary ware.

NANJING TOTO Co., Ltd. Melting Facility

NANJING TOTO Co., Ltd. Melting Facility

Exterior of the hydrogen generation facility building

Exterior of the hydrogen generation facility building

・Introduction of energy-saving equipment, others

In order to reduce CO2 emissions, we are strengthening building insulation (using roof insulation, wall insulation, and double-glazing), using high-efficiency air conditioners and total heat exchangers, adopting LED lighting, and introducing energy monitoring systems at our plants in Japan and overseas.

TOTO Fine Ceramics LTD.Nakatsu Plant 4

TOTO Fine Ceramics LTD.Nakatsu Plant 4

Heat source consolidation for clean rooms

Heat source consolidation for clean rooms

・Introduction of renewable energy At each of our bases in Japan and overseas, we procure electricity derived from renewable energy sources (hereinafter referred to as "renewable electricity") in accordance with the characteristics of the region, and have achieved 100% renewable electricity at multiple bases.

At each of our bases in Japan and overseas, we procure electricity derived from renewable energy sources (hereinafter referred to as "renewable electricity") in accordance with the characteristics of the region, and have achieved 100% renewable electricity at multiple bases.

The global renewable energy electricity introduction volume in FY2024 will be approximately 120GWh, with the renewable electricity ratio being approximately 37%.

We aim to source all electricity used in our business activities from renewable energy sources by 2040, and have joined the international initiative "RE100," with plans to further expand our efforts.

・Conduct of energy saving diagnostics The TOTO Group conducts internal energy conservation audits at its manufacturing and distribution bases in Japan. Based on a set of evaluation indicators common to the Group, energy management specialists conduct comprehensive evaluations of processes, such as the energy management status of production equipment and facilities (air conditioning, lighting, and infrastructure equipment) and compliance with laws and regulations, as well as performance, such as efficient production and active energy-saving activities. The sites that meet these standards are certified as TOTO Green Factories.

The TOTO Group conducts internal energy conservation audits at its manufacturing and distribution bases in Japan. Based on a set of evaluation indicators common to the Group, energy management specialists conduct comprehensive evaluations of processes, such as the energy management status of production equipment and facilities (air conditioning, lighting, and infrastructure equipment) and compliance with laws and regulations, as well as performance, such as efficient production and active energy-saving activities. The sites that meet these standards are certified as TOTO Green Factories.

・Energy Conservation Activities in Our Business sites

The TOTO Group encourages all employees at each Business site to participate in energy-saving activities.

Looking at our monthly performance management, we visualize power use in each workplace based on the data from our data collection system, which centrally manages data concerning the amount of energy used all Group Companies. Energy conservation measures are being driven at each of our office and bases by the feedback this enables.

As part of our efforts in the seasons when the air conditioning load increases across the entire TOTO Group in Japan, we support the initiative "COOL CHOICE" promoted by the Ministry of Environment, and have implemented Cool Biz and Warm Biz, promoting energy conservation and CO2 reduction activities with the participation of all employees at each Business site. We will continue to work to establish awareness of energy conservation among all employees, and will continue to make organizational efforts to help prevent global warming.

[Poster promoting energy conservation in offices]Cool Biz(2025 Summer)

[Poster promoting energy conservation in offices]Cool Biz(2025 Summer)

[Poster promoting energy conservation in offices]Warm Biz(2024 Winter)

[Poster promoting energy conservation in offices]Warm Biz(2024 Winter)

・Initiatives to reduce CO2 emission of company cars

We are promoting initiatives to reduce CO2 emission of company cars by reducing fuel usage. Through creating TOTO's own eco drive system for company cars used in Group companies in Japan, we are improving the eco driving skill by enabling drivers to see the fuel consumption. In addition, standards for purchasing vehicles are formulated to purchase vehicles that are optimum depending on its travel distance and frequency of usage and reduce fuel consumption.

Green Factory Initiatives

As for the new plant, we have installed the latest and most advanced production equipment to improve productivity. At the same time, building insulation has been strengthened (roof insulation, wall insulation, and double-glazing), production air conditioning has been optimized and total heat exchangers have been adopted, LED lighting has been adopted, and an energy monitoring system has been installed to make the plant more environmentally friendly with lower CO2 emissions.

The new west building at TOTO's Shiga Plant was equipped with high-efficiency equipment such as a latest fiber kiln and LED lighting, and exterior walls were coated with Hydrotect Color Coat, an environmental building material that is TOTO's one-of-a-kind technology. As a model factory project that introduced cutting-edge energy-saving technologies, the Shiga Factory received the Minister of Economy, Trade and Industry Award, the highest award in the Energy Conservation Case Study Category of the 2013 Energy Conservation Grand Prize (sponsored by the Energy Conservation Center, supported by the Ministry of Economy, Trade and Industry).

The TOTO Group is developing similar energy-saving factories in Japan and overseas.

May 2022 New Kiln Firing Ceremony at TOTO SANITECHNO Kokura Plant

Initiatives to reduce transport fuel - promoting green logistics

To reduce CO2 emissions, we are striving to decrease the consumption of transport fuel, TOTO is working with transportation companies and sales dealers to increase transportation efficiency, in particular, by improving loading efficiency and conducting joint deliveries.

In fiscal 2024, we will actively promote the introduction of energy-efficient vehicles*1 by our logistics partners and the modal shift to ship transport, which began in fiscal 2023.

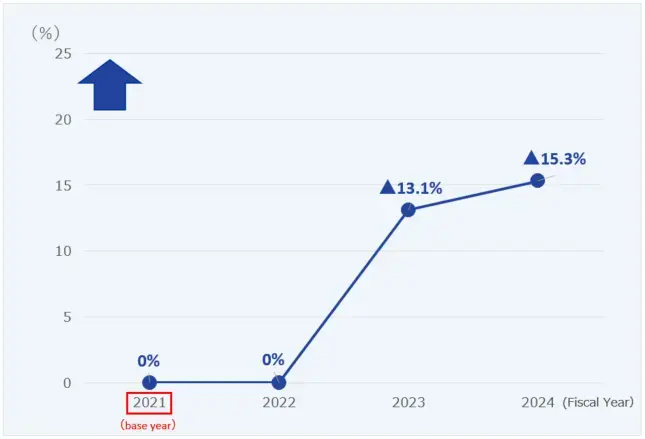

In addition, by participating in the SBT1.5℃ initiative*2, we set higher targets than ever before and further strengthened our reduction activities, resulting in a reduction of 15.3% compared to fiscal 2021.

Reduction rate of transport fuel basic unit at domestic sites(compared to FY2To1)

*1:For 2023, a calculation formula was adopted that took into account the latest evaluation of the introduction of energy-saving vehicles published by the Ministry of Economy, Trade and Industry.

*2:Activities to achieve the greenhouse gas reduction target for 2030 (2030 target: -25% reduction compared to fiscal 2021)

Example of reducing transport fuel

・Product transportation

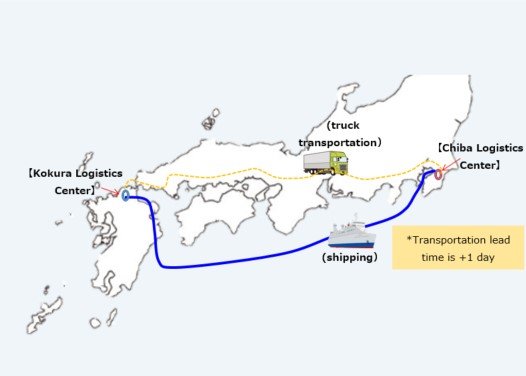

Regarding the long-standing issue*3 of extending the transportation lead time by one day, the Sales Division, production department, and logistics department worked together to solve the issue, enabling a modal shift, and part of the transportation between the Kyushu area and the Kanto area was changed from truck transportation to ship transportation.

*3: In the case of shipping by ship, the transportation lead time is longer than that of truck transportation.

・logistics and transportation

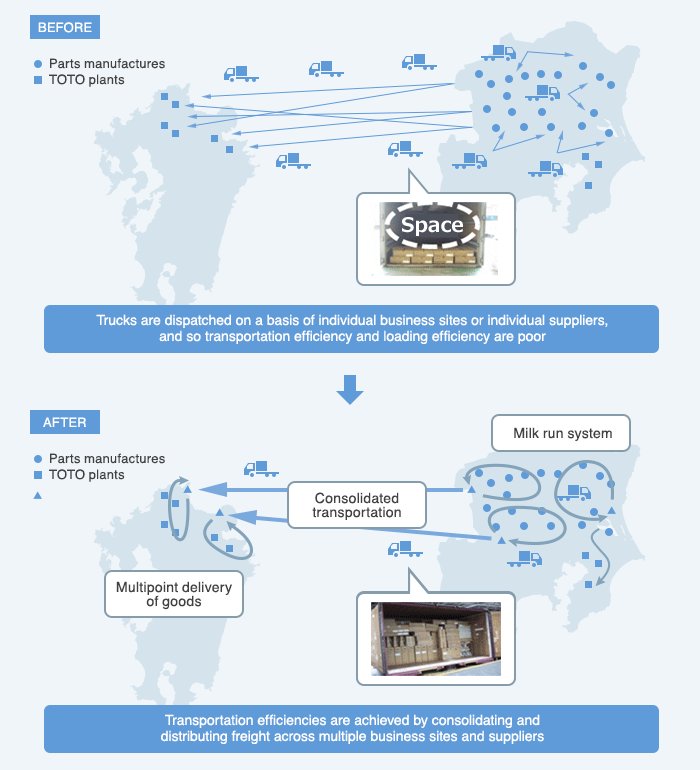

The collection of (parts maker) of each supplier collected cargo by one truck, and TOTO carried out "the supply physical distribution" which delivered a lump to TOTO plant from 2014 and wrestled by CO2 reduction by the truck reduction. I build a distribution infrastructure network to Kanto - Kyushu now. I plan transportation efficiency by investigating all company horses for courses style, and coming true and will aim at the Environmental load reduction in future.

Current state and future vision for procurement and transportation

・System kitchen

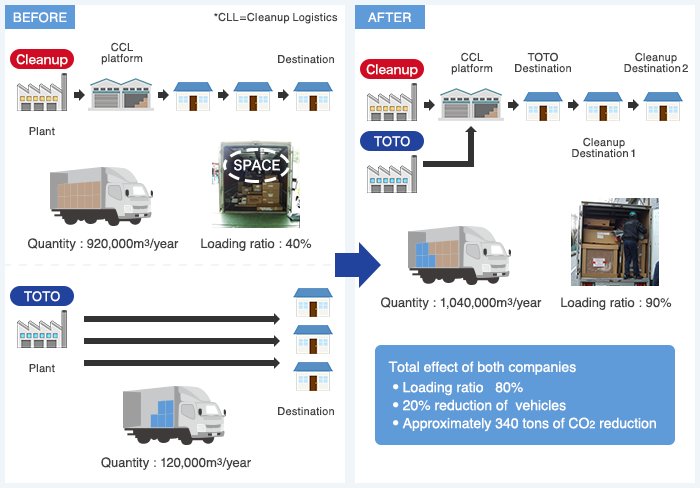

TOTO carries out "the cooperation delivery" beyond the fence in the delivery of the system kitchen in the every prefecture except the part area in Cleanup Corporation having a competing relation on a sale side and a distribution side.

I am improved in future and realize reduction of the truck vehicle number, the improvement of the loading rate (this theme won "Councillor Ministry of Economy, Trade and Industry commercial affairs distribution preservation commendation" in "green distribution partnership excellence company commendation" in 2015) and work on Environmental load reduction.

・Example of improved use of fuel in transportation (Thailand)

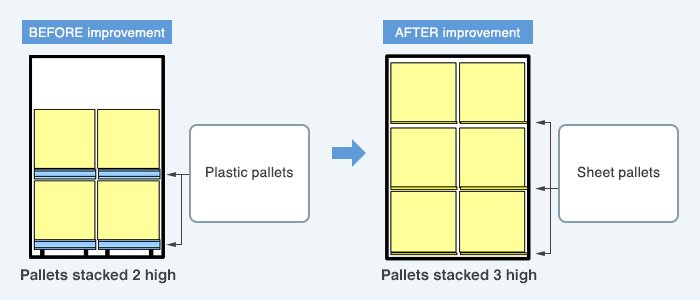

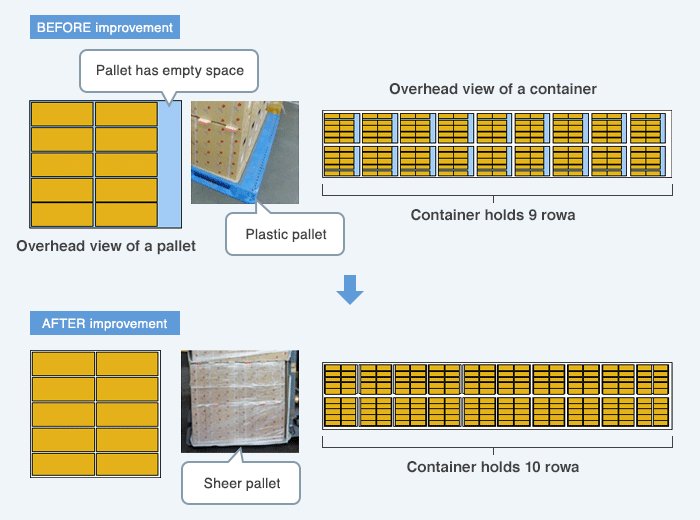

We improved loading efficiency by changing the pallets used when loading containers, from plastic pallets to sheet pallets.

(1) By enabling pallets to be stacked 3 high, loading efficiency was improved by 50%.

(2) Previously, pallets had had empty spaces.By changing to sheet pallets, we were able to fill in the empty spaces, and loading efficiency improved by 11%.

Initiatives for Products

Improvement and promotion of water-saving and energy-saving performance of products, Efforts to reduce CO2 through the use of recycled materials

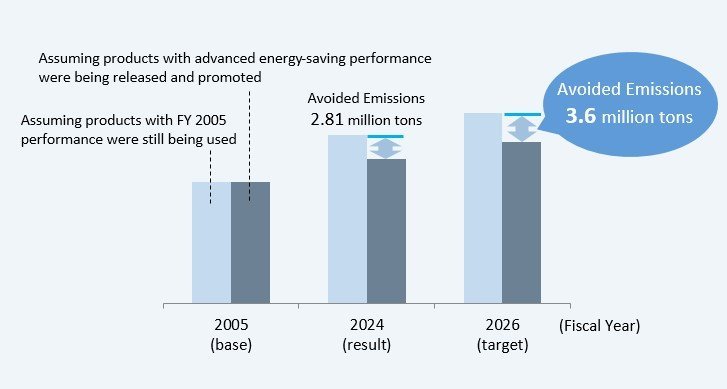

The TOTO Group is promoting efforts to reduce CO2 emissions during product use and thus prevent global warming, by expanding the sales of water- and energy-saving products on a global scale. We defined the Avoided Emissions during product use as the amount of reduction in CO2 use compared to the case where we have been spreading the use of the then product range in 2005. we set specific targets and manage their progress. Since the amount of Avoided Emissions during product use will increase as more customers use products with high water-saving and energy-saving performance, we aim to achieve the target of Avoided Emissions during product use through efforts such as improving water-saving and energy-saving performance and further promoting the spread of high-performance products.

The Group reduced 2.81 million tons in fiscal 2024 and is targeting a reduction of 3.6 million tons in fiscal 2026 under WILL 2030 STAGE 2, a strategy to achieve a carbon-neutral and sustainable society by 2050. In addition, the TOTO Group is actively using recycled plastics to reduce CO2 emissions generated during the procurement of raw materials.

Transition of Avoided Emissions during product use *For more information on Avoided Emissions during product use, click here, and for the calculation conditions of main products, click here.

*For more information on Avoided Emissions during product use, click here, and for the calculation conditions of main products, click here.

Bathroom Water Conservation Initiatives

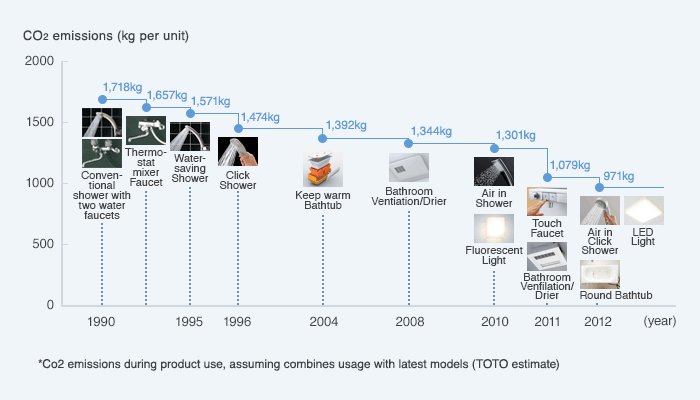

TOTO has continued to undertake development of water-saving showers, insulated bathtubs, etc., and has been working to improve the water-saving and energy-saving performance of the bathroom which uses more energy than any other plumbing equipment in the home.

Progress made in reducing CO2 emissions generated during the usage of products in the bathroom

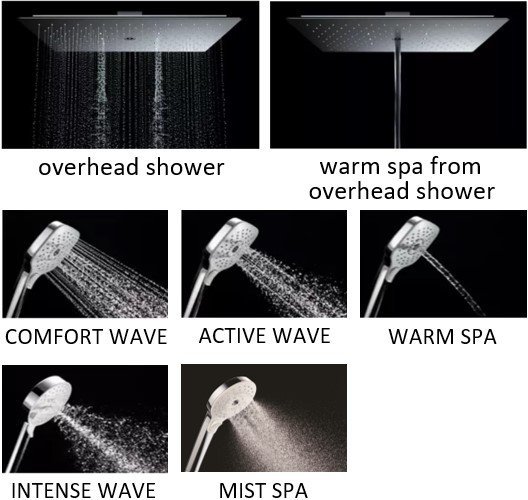

・Comfort Wave Shower

TOTO's proprietary nozzle can produce large drops of water and powerfully spray and swing them. This technology realizing both water-saving and comfortable stimulation contribute to reduce CO2 emissions.

Comfort Wave account for over 70% of all TOTO showers for bathrooms shipped domestically.

Optimal water flow: 6.5 L/minute

(35% savings over conventional shower *)

*Conventional shower model number: TM245CS

Compared to our company's product, it's based on the optimal flow rate. The optimal flow rate is the "flow rate that internal monitors feel is the easiest to use," measured based on the method stipulated by the Japan Valve Manufacturers' Association.

・Expansion overseas

TOTO has also deployed the technology and environmental performance of Comfort Wave Shower overseas.

We have advanced a number of product variations according to the overseas culture of showering and depending on the characteristics of each region.

We are committed to promoting the wider use of this technology.

Efforts to Reduce Electricity Consumption by WASHLET®

・Instantaneous water heating system

Hot water is produced only when it is used. The water does not become cold even if it is used continuously. Reducing electricity consumption to keep the water warm also reduces associated CO2 emissions.

Water is stored in a tank, heated by a water heater and used for washing.

Hot water is only produced when needed for washing.

In addition, further energy savings are achieved through functions such as the instantaneous toilet seat warmer, which activates only when the toilet is in use, and the temperature-adjustable seat warmer, which detects periods of low usage and automatically lowers the seat temperature.

*Products sold and functions available vary depending on the country or region.

Utilization of Recycled Plastic

In the tank part of toilets, more than 80% recycled plastic is utilized.

The use of Recycled plastic reduces CO₂ emissions generated during raw material procurement compared to Non-recycled plastic.

We are increasing the adoption of recycled plastic in other components such as washlets, system baths, and kitchens.

For more information on Use of Recycled Plastic, click here.

お気に入りに保存しました