Resource Circulation

Our Approach

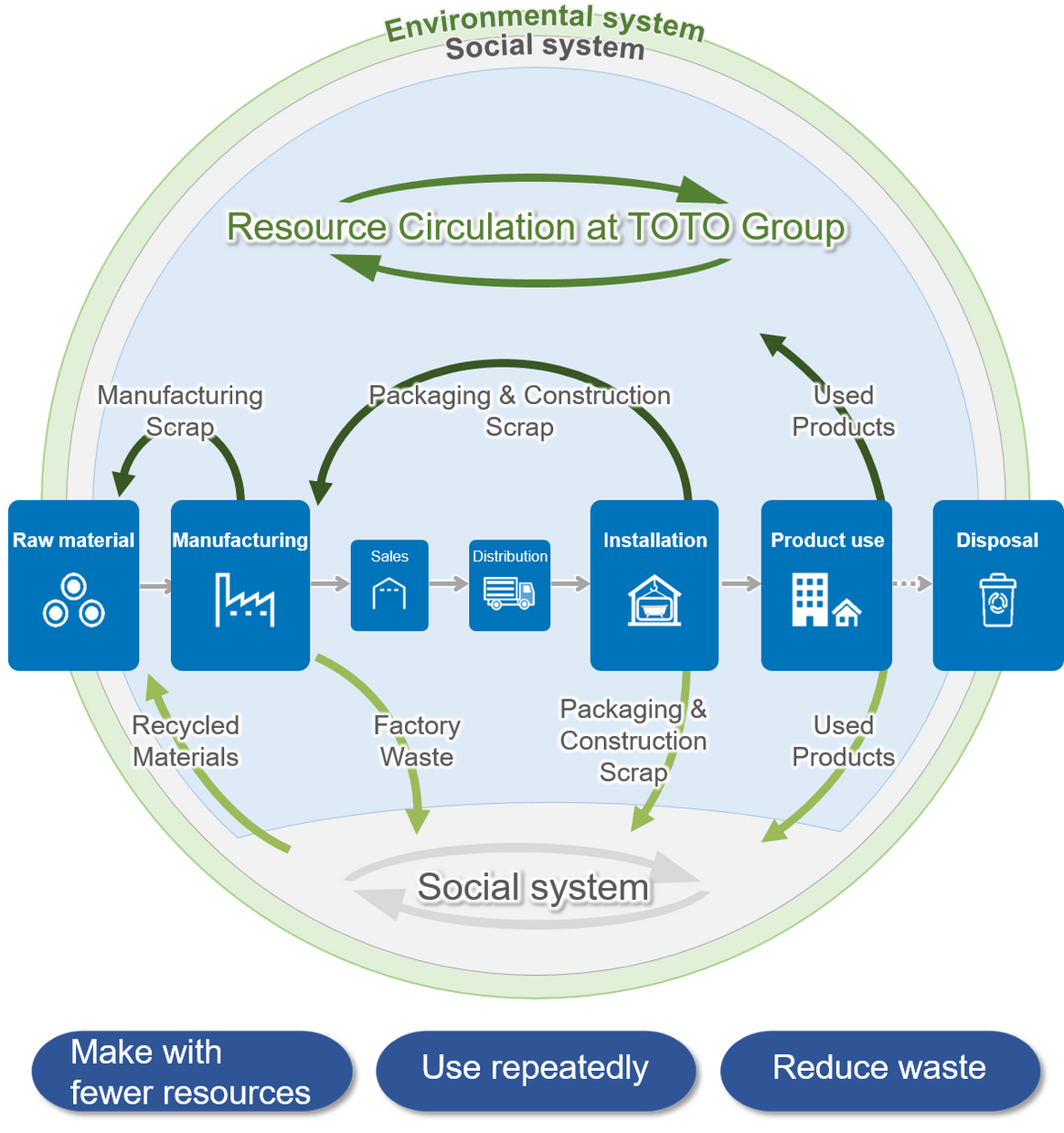

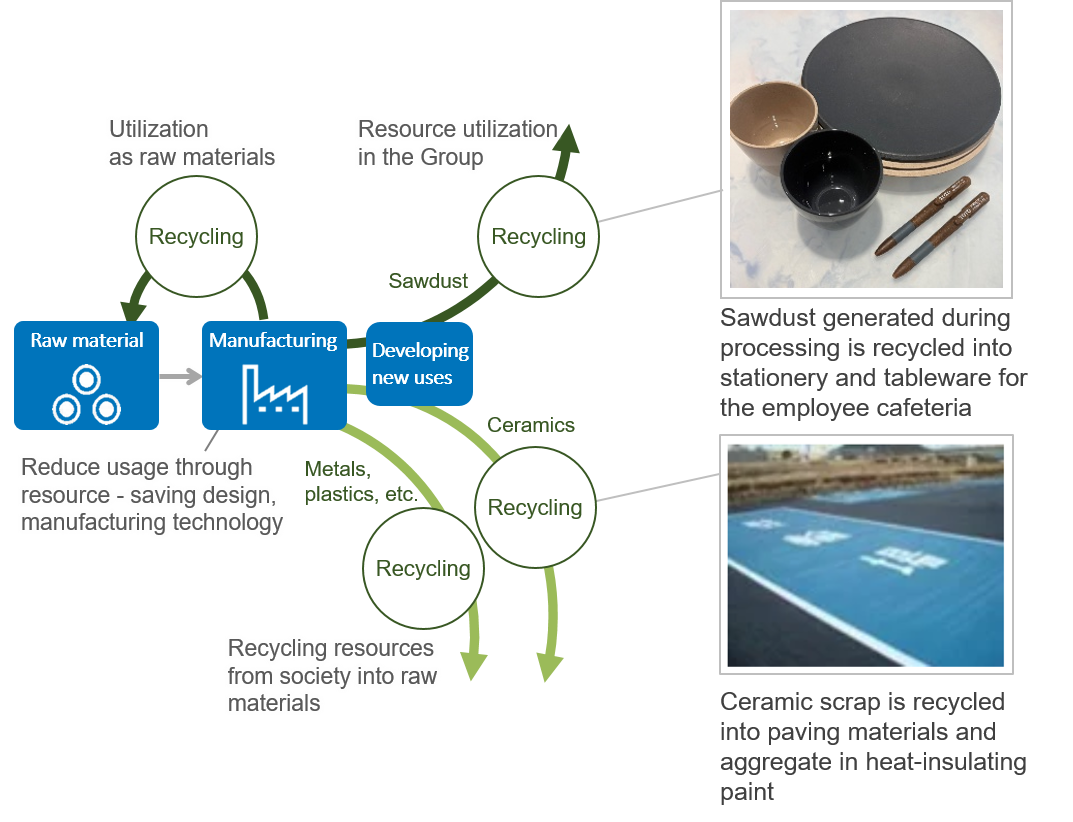

In order for the TOTO Group to remain an organization that can continue to contribute widely to society and the global environment, we are promoting initiatives to reduce resource input and disposal to the environment at all stages, from product design to disposal after consumption while also leveraging societal mechanisms.

Raw materials

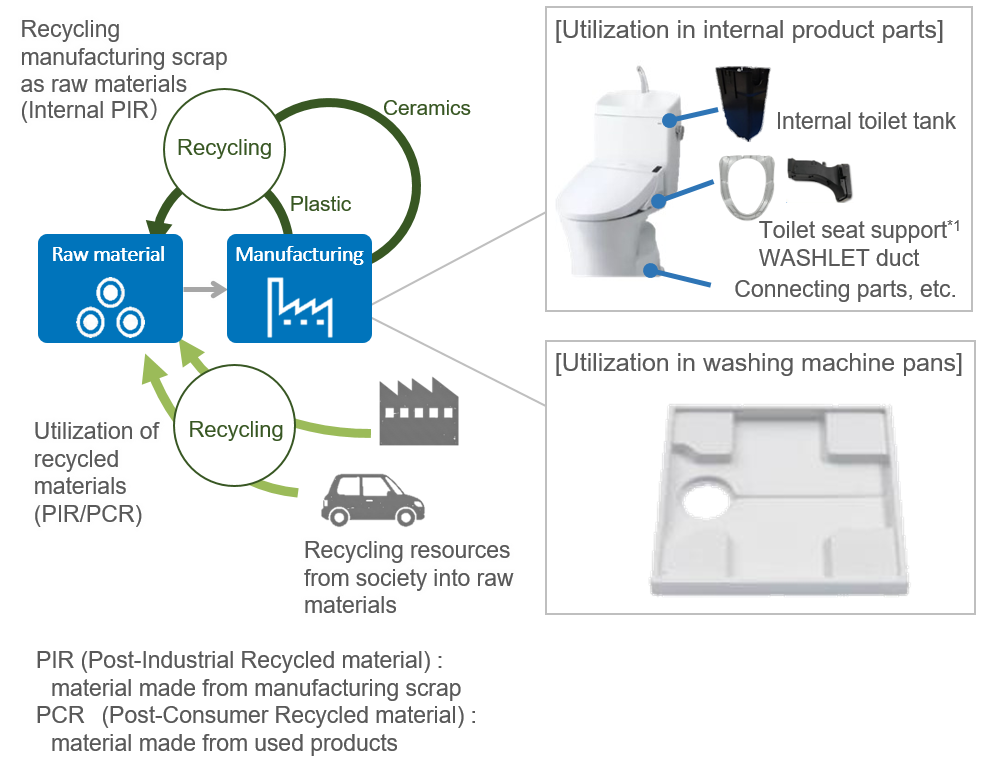

We are promoting initiatives to decrease the use of natural resources, such as reducing resource use and product weight in the product design phase while also proactively using recycled materials.

・Promoting the use of recycled plastics

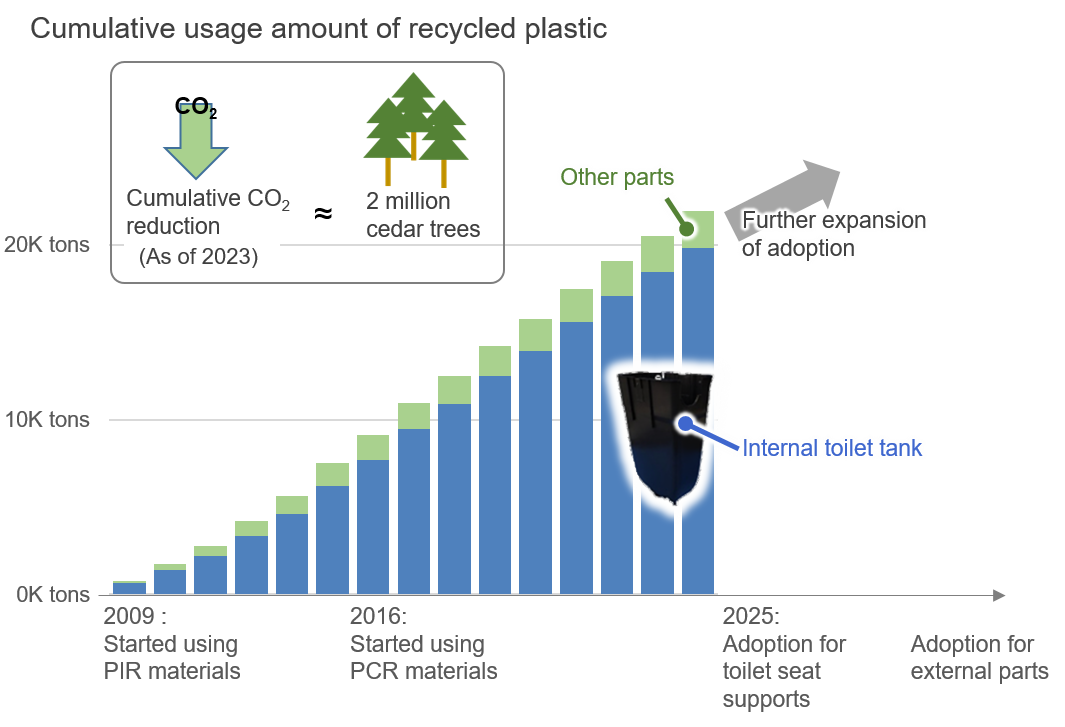

We began using recycled plastics as raw materials ahead of others. In 2009, we started using post-industrial recycled materials (PIR materials) made from manufacturing scrap as the raw material for the internal tanks of toilet tanks. In 2016, we added post-consumer recycled materials (PCR materials) produced from used products, further expanding our use of recycled plastics.

The cumulative amount of recycled plastic we have used exceeded 20,000 tons by 2023. Compared with a case in which we continued to use virgin materials (natural resources), this corresponds to a reduction in CO2 emissions equivalent to the amount absorbed by about 2 million cedar trees in one year*2.

*2 Based on data (one cedar tree absorbs approximately 8.8 kg of CO2 per year) published on the webpage “Preventing Global Warming > How Much Carbon Dioxide Do Forests Absorb?” (in Japanese) by the Forestry Agency of Japan.

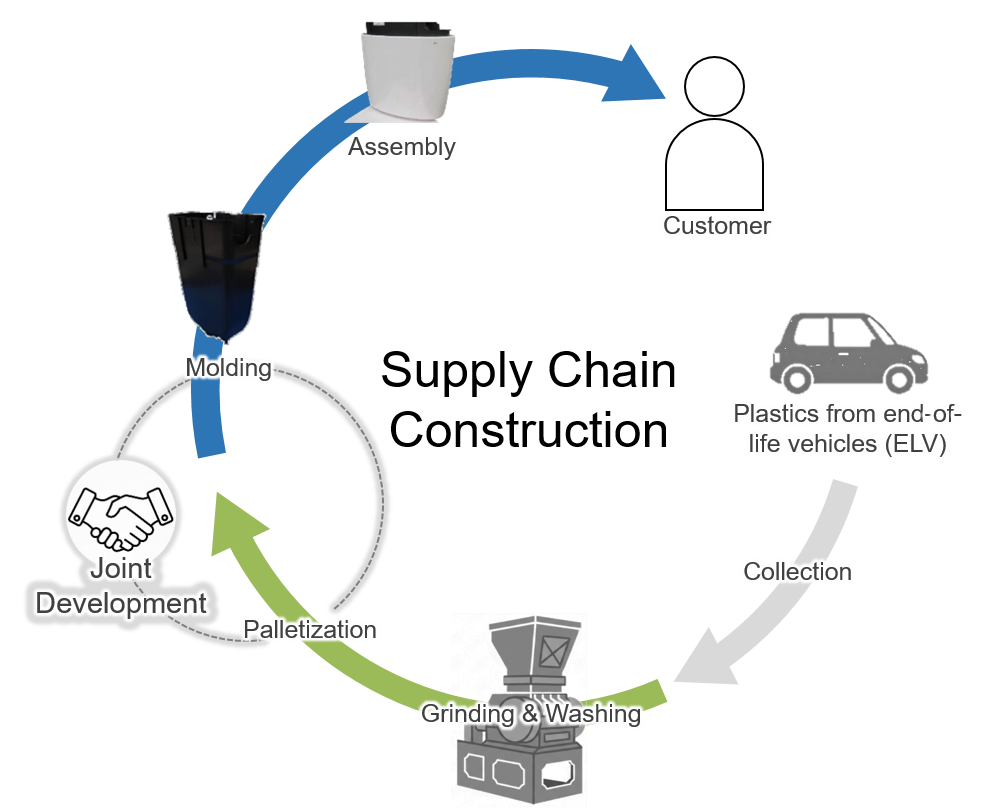

When using recycled plastics, it is important to ensure the quality needed to provide sufficient product durability and to maintain precision in size. When we expanded the use of recycled materials from PIR materials to PCR materials, we developed new materials with the support of Ohmi Bussan and explored a variety of aspects, including securing raw materials and developing material colors. We now have a supply chain that can secure stable PCR materials in both quality and quantity, using plastics derived from end-of-life vehicles and other raw materials.

We will continue to explore the use of recycled plastic materials in white products and products with decorative designs so that we can employ recycled plastics in parts that are visible from the outside, thereby further promoting our use of recycled plastics.

Manufacturing

We are reducing the resources used to produce our products by developing manufacturing technologies that reduce the generation of manufacturing scrap.

We are reducing the disposal of resources into the environmental system by promoting both internal and external recycling of generated manufacturing scrap and by ensuring the proper management of waste from our business activities through reduction and recycling based on the environmental management system.

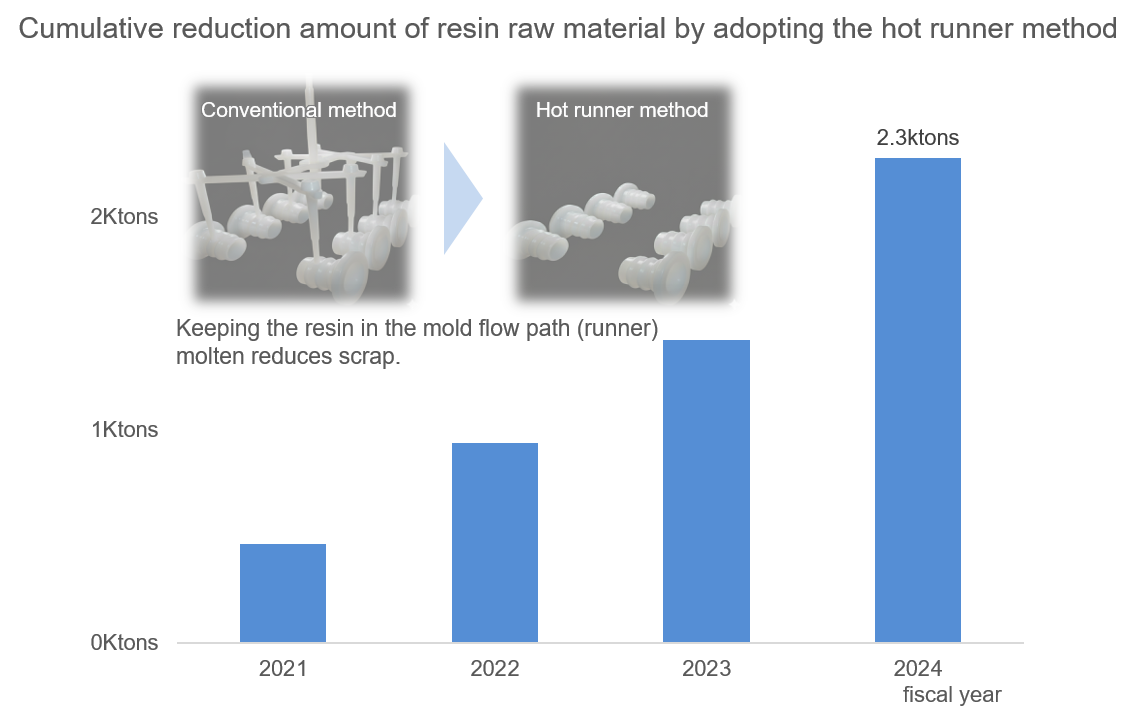

・Initiatives to reduce manufacturing scrap through manufacturing technologies

We are reducing wasteful use of resources by utilizing ”the hot runner method”, a manufacturing technology that can reduce manufacturing scrap generated in the plastic injection molding process.

・Zero emission initiatives

We have achieved zero emissions*3 at all manufacturing sites in Japan through waste reduction and recycling. We are also working to achieve zero emissions at overseas manufacturing sites by prioritizing the recycling of ceramic scrap, sludge, and mineral scraps.

*3 Definition of TOTO Zero Emissions

(Based on ideas put forward by the United Nations University in 1994)

To pursue virtually zero landfill (including simple incineration) of general and industrial waste from our plants.

(The target for "virtually zero waste" is a recycling rate of 99% or higher.)

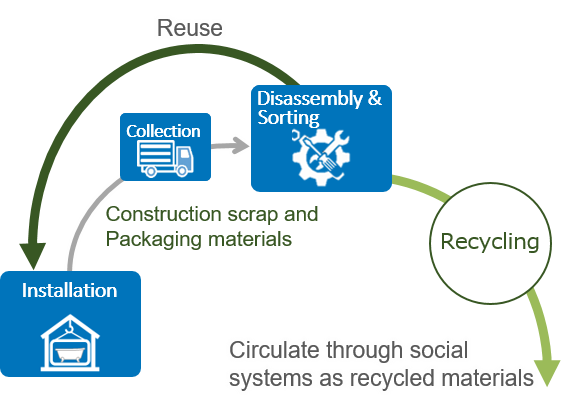

Installation

We internally design packing materials that protect our products from the shipment to installation phases, ensuring high packaging quality while minimizing the resources required.

We also promote the effective use of resources by collecting packaging materials and installation scrap.

・Reduction of packaging materials

Packaging materials play an important role in protecting products from damage and scratches caused by impacts between the shipment and installation phases. By using corrugated cardboard as the cushioning material and integrating it into the box, the entire package is made from the same material, making it easy to sort. Moreover, by pursuing optimal shapes, our packaging can be made using reduced resources while ensuring packaging quality, including cushioning performance and workability. These material- and man-hour-saving packaging materials have been highly regarded both in Japan and abroad (received an award at a packaging contest*4).

*4 Soft-touch corrugated cardboard cushioning material, packaging with a shock-absorption function for artificial marble counters, etc.

・Collection and recycling of packaging materials and installation scrap under the wide-area certification system

We collect*5 packaging materials and installation scrap generated at construction sites and reuse or recycle them to reduce the amount of resources disposed of.

Scope of Authorized Collection

The authorization covers packaging and construction materials for unit bathrooms, modular kitchens, system toilets, sanitary ware, toilet seats, tiles, faucets, and plastic bathtubs. It also includes products found to be unusable upon delivery due to breakage, etc.

Authorized Collection Areas

Operations under this authorization began in October 2007 in areas where the collection system was established.

*5 We collect materials under the Wide-Area Certification System, a special exception to Japan's Waste Management and Public Cleansing Act.

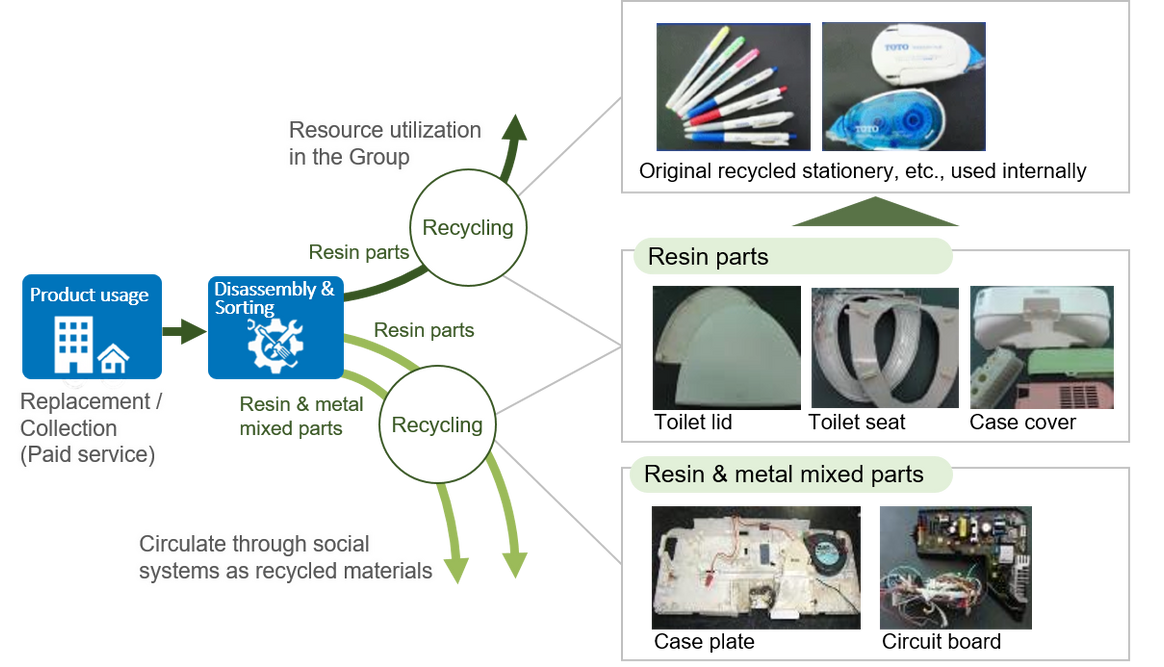

Used products

With the aim of recycling end-of-life products as resources, we use the wide-area certification system and implement a system to collect used Washlets in some areas.

After collecting Washlets, they are washed, disassembled, sorted, and then used as recycled resources.

We will continue to advance our contributions to more advanced resource recycling by researching products designed for easy recyclability and by exploring recycling technologies and potential applications for recycled materials.

Partnerships

We participate in the Japan Partnership for Circular Economy (J4CE) led by the Ministry of the Environment and in Circular Partners (CPs) led by the Ministry of Economy, Trade and Industry to identify solutions to recycling and waste-processing challenges that are difficult to solve on our own, through collaboration with partners across diverse industries.

お気に入りに保存しました